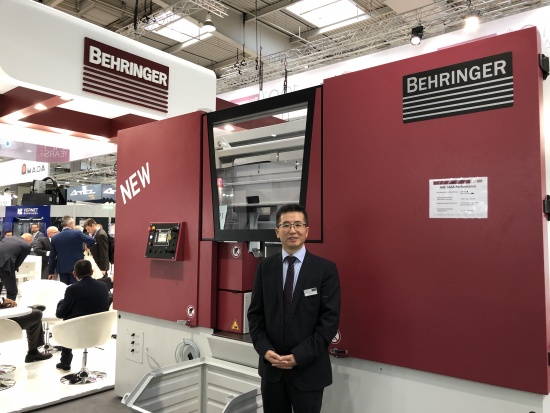

Dongdong Tao of Behringer (Shenyang) Machinery Co. Ltd,

speaks to APMEN about the company’s presence in Asia.

Dongdong Tao, e xecutive director and general manager of Behringer (Shenyang) Machinery Co. Ltd, speaks to Asia Pacific Metalworking Equipment News about the company’s presence in Asia, opportunities in the market, and their latest technology innovations. Article by Stephen Las Marias.

Behringer GmbH is one of the biggest names in bandsaws and circular saws worldwide. Celebrating its 100th year this year, the company—now run by Rolf and Christian Behringer, the grandchildren of founder August Behringer—mainly has three production bases: one in Kirchardt, Germany, the headquarters, which produces bandsaws; one in the southern part of Stuttgart, which is a circular saw manufacturer; and the third production base in France, which is a joint venture between Behringer and Vernet.

Most of the machines that Behringer produces are exported to over 80 countries. Behringer has sales and service subsidiaries in the United States, France, China, and the United Kingdom, and over 30 agencies worldwide.

At the recent EMO Hannover 2019 trade fair, Dongdong Tao, ex ecutive director and general manager of Behringer (Shenyang) Machinery Co. Ltd, speaks to Asia Pacific Metalworking Equipment News about the company’s presence in Asia, opportunities and challenges in the market, and their latest technology innovations.

Tell us something about yourself and your role in the company.

What opportunities are you seeing in the Asian market?

Considering the rapid economic development in countries such as China, Vietnam, and Singapore, and the fast-catching markets of Malaysia and the Philippines should be among the future markets for Behringer.

Are there any particular industry or industries you are seeing strong growth?

What are some of Behringer’s sawing technologies being highlighted at the show?

DT: One of our highlights for this exhibition is the new model HBE 560A Performance. HBE Performance is a relatively new series, which was launched only about two years ago. We have different models under this series. This new model completes the cutting range of the HBE series from 560mm to 1m.

The special advantage in technology in this series is the down-feed design of ball spindle and servo-motor.

When you look at the market now, most bandsaws you will see use hydraulic down-feed. The spindle and servo design is mostly used in high-rank products, but now we use it in our regular sawing machines series.

What is the advantage of this?

With this new design, you can significantly increase your performance. But the price of the machine is similar to previous hydraulic models. The same price, but at a higher accuracy and higher efficiency, this will be attractive for customers.

What is your outlook for the next year?

In Asia, I think we are also reading about this kind of topic, but it is not as critical as in Europe.